Pipe Bursting Cost Calculator

Total Cost: $0

**The above is not a proposal/Estimate, please visit our Pipe Bursting Service Pages to get pricing specific to your project in your area. Please read on to learn more.

Material Considerations

Different Pipe Materials and Their Cost Implications

The choice of pipe material plays a significant role in determining the overall cost of a pipe bursting project. Options range from PVC and HDPE to more durable materials like cast iron or clay, each with different price points. The longevity and cost-effectiveness of these materials should be carefully considered in the planning phase.

Labor and Expertise

The skill level of the workforce executing a pipe bursting operation influences the project’s cost. Specialized training and certifications are required for handling the sophisticated equipment involved in trenchless technology. These factors contribute to the labor costs, underscoring the importance of hiring experienced professionals.

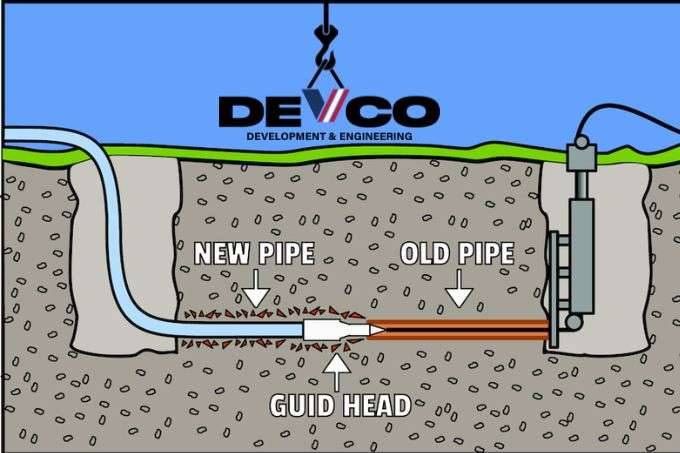

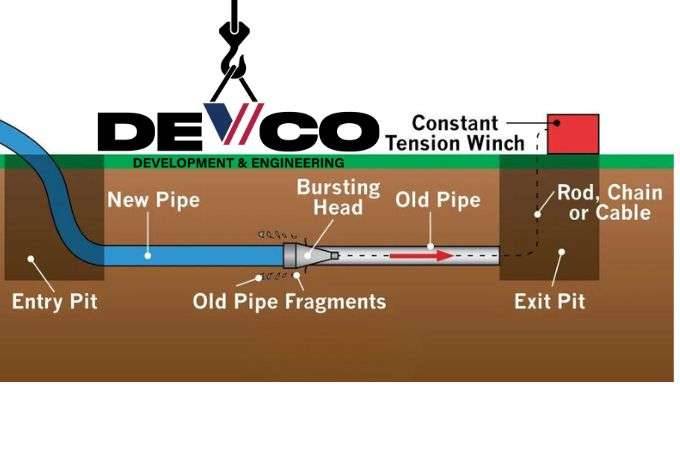

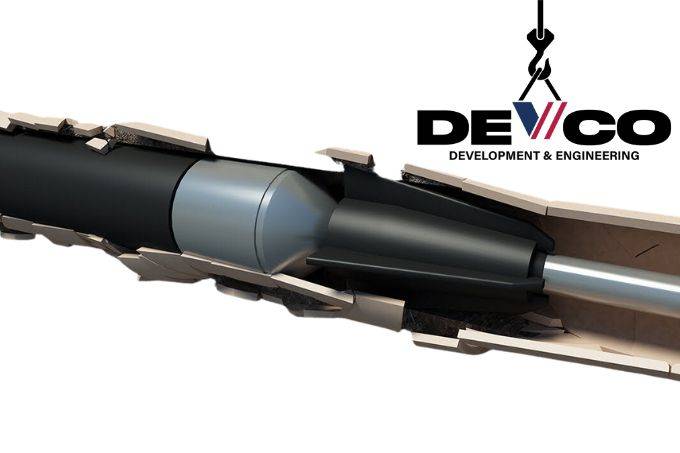

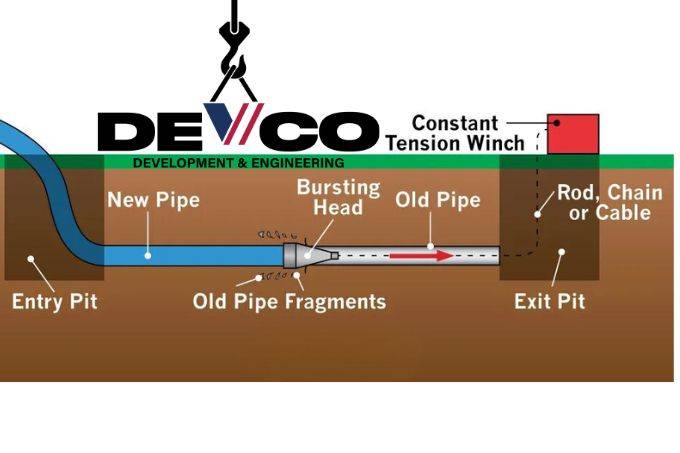

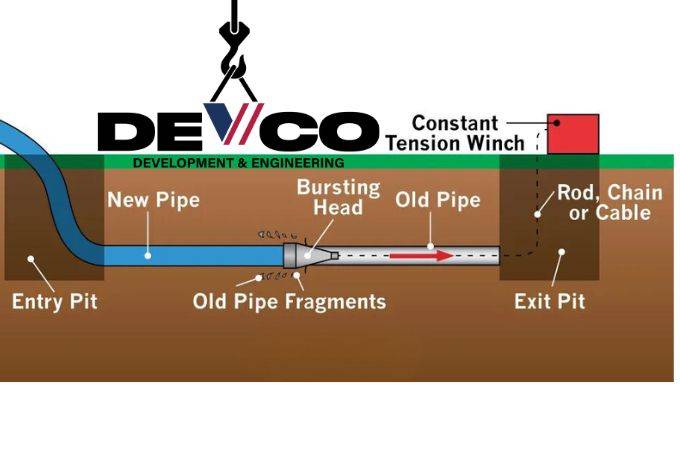

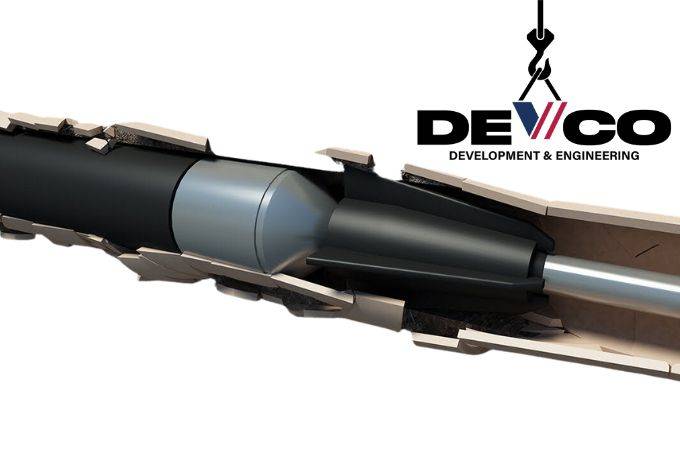

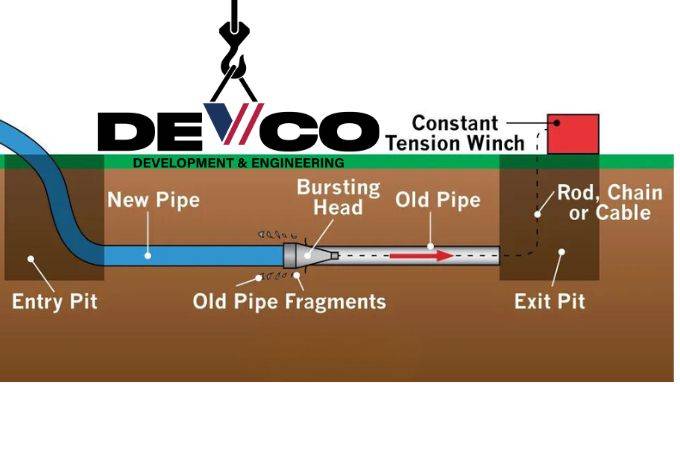

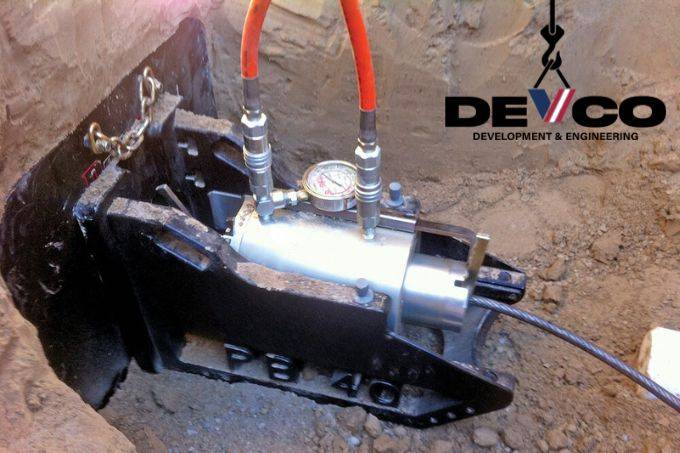

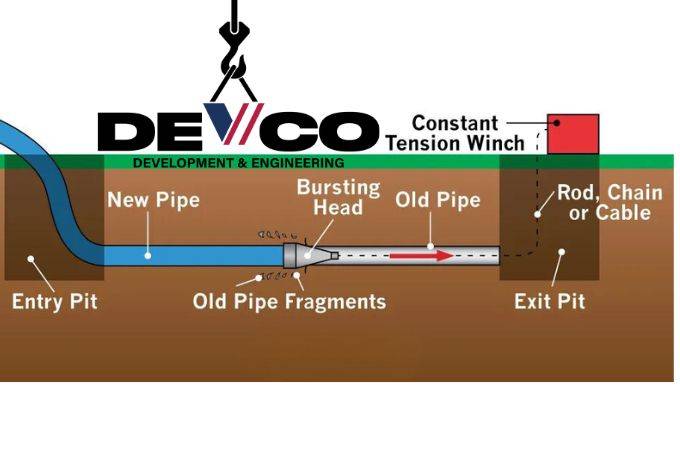

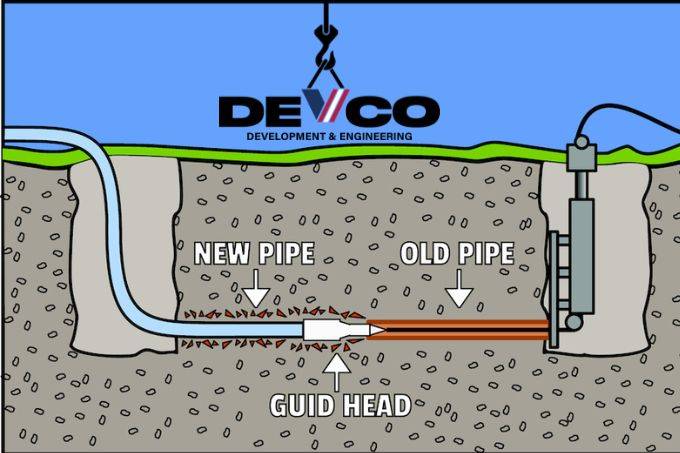

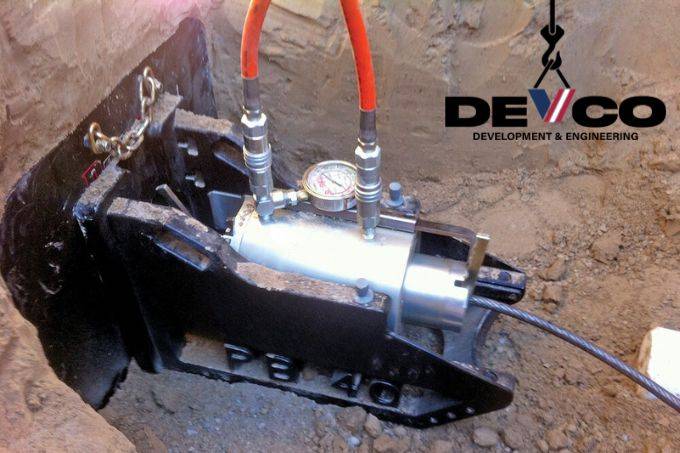

Equipment and Technology

Investing in high-quality pipe bursting equipment is crucial for the success of a project. Modern trenchless technology comes with a significant price tag, but the cost benefits in terms of reduced labor and minimal disruption often justify the investment.

Project Complexity

How Complexity Affects Pricing

The complexity of a pipe bursting project, including factors like depth, soil type, and access issues, has a direct impact on pricing. Residential projects might be less complicated and therefore less expensive than commercial endeavors, which typically involve larger-scale operations.

Permits and Regulations

Local regulations and the necessity for permits can add to the overall cost of a pipe bursting project. Permitting fees and legal considerations should be anticipated in the project budget.

Geographical Location

Cost variations are also influenced by regional factors, including the availability of skilled labor and the cost of materials. Additional costs might arise from transportation or logistical challenges specific to the project’s location.

Site Preparation and Restoration

Preparing the site for pipe bursting involves certain expenses, as does the restoration of the area post-operation. Effective cost management strategies are essential to keep these costs under control.

Environmental Impact

Trenchless pipe replacement is favored for its reduced environmental impact. The cost considerations for working in environmentally sensitive areas, alongside the savings from diminished ecological disruption, should be factored into the project’s budget.

Cost-Benefit Analysis

Long-Term Financial Benefits

Although the upfront costs of pipe bursting might seem high, it’s crucial to perform a thorough cost-benefit analysis. The long-term savings from choosing a durable, less disruptive method can outweigh initial expenditures.

A Look at the Numbers

Insights from NapaSan’s AC Pipe Bursting Project

The NapaSan AC Pipe Bursting Project demonstrates significant cost savings when compared to traditional methods. Traditional open cut construction and removal of AC pipe could cost around $450 million, or $750 per linear foot, including major roadway restoration and AC pipe disposal. In contrast, pipe bursting was estimated at approximately $81 million, or $135 per linear foot, marking an 85% reduction in excavation and associated costs.

Conclusion

Pipe bursting presents a modern solution to pipe replacement, offering several benefits over traditional methods. By incorporating specific project data and costs, stakeholders can make more informed decisions that align with their budgetary constraints and long-term objectives. Always consider consulting with trenchless technology experts to get accurate estimates and tailored advice for your specific project.