Request for Contact/Quote

Have an urgent request? Let us know here and we will have someone reach out ASAP.

Introduction

Underground utilities are the silent arteries of our cities, providing essential services that fuel our daily lives. From the water we drink to the sewage systems that maintain our hygiene, the integrity of these hidden networks is crucial. But with time, these vital pipes age and fail, necessitating efficient and effective renewal strategies.

In the past, repairing or replacing these critical conduits meant extensive excavation, with large trenches disrupting traffic, businesses, and community life. However, the dawn of trenchless technologies has revolutionized underground utility work. These innovative methods allow for the repair or replacement of pipes with minimal surface disruption, offering a beacon of progress in urban infrastructure maintenance.

DEVCO stands at the forefront of this revolution, employing two key trenchless methods: pipe bursting and pipe splitting. These techniques, while similar in their minimally invasive approach, have distinct applications and benefits. In this blog post, we will:

Join us as we delve into the world beneath our feet and explore how the right choice between pipe bursting and pipe splitting can lead to smarter, cleaner, and more efficient utility renewals.

What is Pipe Bursting?

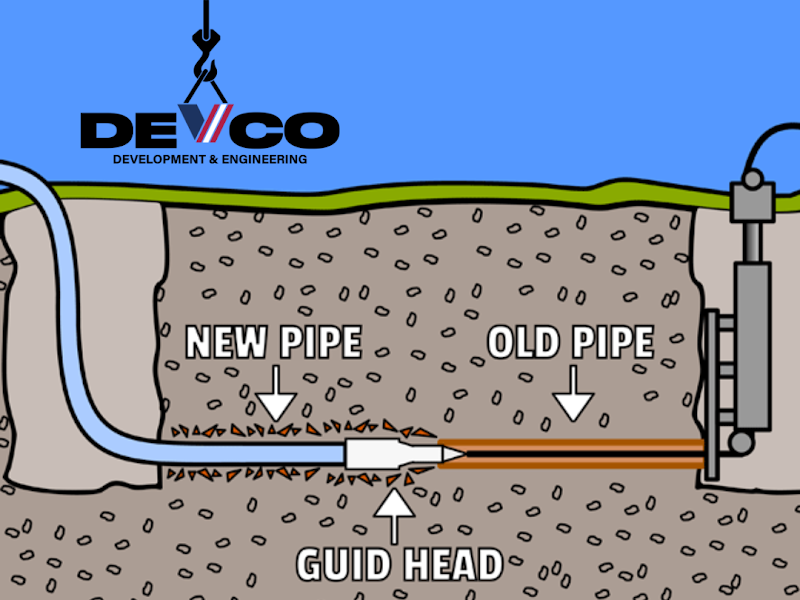

Pipe bursting is a state-of-the-art trenchless rehabilitation method designed to replace buried pipelines without the need for a traditional construction trench. By seamlessly integrating into the existing pipeline route, this technique minimizes surface disruption while effectively renewing underground utilities.

The Process of Pipe Bursting

The pipe bursting process is a marvel of modern engineering that unfolds through the following steps:

Suitable Pipe Materials: Pipe bursting is versatile and can be applied to a variety of pipe materials, including cast iron, clay, concrete, and PVC. However, the specific conditions of each pipeline can affect the method’s applicability.

Benefits of Pipe Bursting

Pipe bursting offers numerous advantages over traditional pipe replacement methods:

By embracing these benefits, DEVCO demonstrates its commitment to innovative, sustainable, and community-friendly infrastructure solutions.

Pipe Bursting in Action: A Visual Journey

Watch a demonstration of pipe bursting and see how this technique to rehabilitate aging pipelines:

Understanding Pipe Splitting

Pipe splitting is a specialized trenchless method, often seen as a cousin to pipe bursting, yet distinct in its execution and application. This method is specifically designed for the replacement of pipes that are too tough or too deteriorated for bursting.

What is Pipe Splitting?

Pipe splitting involves the strategic division of an existing pipeline using a splitting head. This technique is often reserved for pipes made of stronger materials such as steel or ductile iron, which are not easily fractured by bursting.

Typical Use-Case Scenarios for Pipe Splitting

The Process of Pipe Splitting

The procedural steps for pipe splitting closely resemble those of pipe bursting but with a key difference in the equipment and execution:

Equipment Highlight: Pipe splitting requires a robust cutting head, capable of handling the pipe’s material. The pulling system must be calibrated to provide the necessary force to split the pipe without causing collateral damage.

Benefits of Pipe Splitting

Pipe splitting is a precise and effective method with several benefits:

By harnessing the power of pipe splitting, DEVCO strategically navigates the complexities of infrastructural renewal, ensuring that even the most challenging pipe materials can be replaced with precision and efficiency.

Witness the Precision of Pipe Splitting: A Guided Demonstration

Experience the meticulous process of pipe splitting through this informative video, illustrating how this technique is deployed in the field.

Comparing Pipe Bursting and Pipe Splitting

Both pipe bursting and pipe splitting have revolutionized the way we approach the replacement of underground utilities. These trenchless technologies share a common goal: to renew infrastructure with minimal impact on the surrounding environment. However, their methodologies and applications have distinct characteristics tailored to specific conditions.

Key Similarities

Before we delve into the differences, let’s consider the core similarities between pipe bursting and pipe splitting:

Key Differences

While the end goal of renewing pipelines is shared, the journey there differs between pipe bursting and pipe splitting:

Technical Execution

Scenarios and Suitability

The decision to use pipe bursting or pipe splitting largely depends on the existing pipeline’s material, condition, and the surrounding environment. DEVCO assesses each project on a case-by-case basis to determine the most appropriate and effective technique.

In conclusion, while pipe bursting and pipe splitting share a trenchless philosophy and a commitment to minimizing disruption, their differences in application and execution are critical for project success. By understanding these nuances, DEVCO ensures that each infrastructure renewal project is approached with the most suitable, efficient, and sustainable technology.

Here is a video showing both techniques and the subtle difference:

How DEVCO Utilizes Both Techniques

DEVCO stands at the forefront of underground infrastructure renewal, wielding a dual expertise in both pipe bursting and pipe splitting. The company’s proficiency in these techniques is underscored by a track record of successful applications in a myriad of environments, tailored to the nuanced demands of each project.

DEVCO’s Expertise in Pipe Renewal

At DEVCO, mastery over trenchless technology comes from a deep understanding of its practical applications and a commitment to continuous learning. The company has a portfolio of projects showcasing its skillful use of both pipe bursting and pipe splitting, emphasizing its versatility and client-centric approach.

Case Study: Recently, DEVCO undertook a large-scale sewer line replacement project in a densely populated urban area. Traditional excavation would have caused significant traffic disruptions and environmental impact. By employing pipe bursting, DEVCO managed to replace the aging infrastructure efficiently, with minimal surface disturbance, thus maintaining the community’s daily rhythm. This project not only showcased DEVCO’s technical ability but also its sensitivity to the needs of the community and the environment.

Choosing the Right Method

DEVCO’s approach to selecting between pipe bursting and pipe splitting is methodical and data-driven. Every project begins with a thorough assessment of the existing pipeline’s material, condition, and the location’s environmental and regulatory constraints.

Factors Influencing the Choice:

In every instance, DEVCO prioritizes the client’s needs and project outcomes. Whether it’s ensuring a quick turnaround to restore critical services or minimizing the impact on a sensitive ecological zone, DEVCO’s team is equipped to make the call that aligns with the overarching project goals.

The judicious choice between pipe bursting and pipe splitting is emblematic of DEVCO’s broader philosophy: to employ the right tools for the right job, ensuring project success while upholding its standards for sustainability and community stewardship.

Conclusion

In the intricate dance of underground infrastructure renewal, choosing the right method for the job is not just a matter of efficiency, but of necessity. DEVCO’s dedication to providing cost-effective, environmentally conscious solutions stands as a testament to their leadership in the field. By leveraging trenchless technologies such as pipe bursting and pipe splitting, DEVCO ensures that every project is executed with minimal disruption and maximal benefit to the community and environment.

Call Devco For you Pipe Bursting and Pipe Splitting Needs

Are you facing the daunting task of replacing or repairing underground pipes? Let the experts at DEVCO guide you through the best trenchless technology solutions tailored for your specific needs. With a commitment to excellence and a proven track record, DEVCO is equipped to handle your pipe renewal projects with the precision and care they deserve.

For a comprehensive assessment or consultation, reach out to DEVCO today:

Don’t let outdated or damaged pipes compromise your infrastructure. Contact DEVCO and secure the future of your underground utilities now.