The Essential Steps of Pipe Bursting: Your Guide to Trenchless Pipe Repair

- Trenchless Technology

- Mar 31

- Share post

Pipe bursting has revolutionized the way underground utilities are installed and repaired, offering a trenchless solution that minimizes disruption and environmental impact. Whether it’s a sewer line, gas line, or any other underground utility, understanding the steps involved in pipe bursting can help you appreciate this innovative method’s efficiency and effectiveness. Let’s dive into the process, outlining each critical stage from preparation to completion.

Understanding Pipe Bursting

Before delving into the steps, it’s essential to grasp what pipe bursting entails. This trenchless technique involves breaking apart an existing, damaged pipe while simultaneously replacing it with a new one. Unlike traditional excavation methods, pipe bursting requires only small access points, reducing surface disruption and making it an ideal choice for urban environments or areas with limited access.

The Steps of Pipe Bursting

Step 1: Initial Inspection and Planning

The first step in the pipe bursting process involves a thorough inspection of the existing pipeline. This is usually done using a closed-circuit television (CCTV) camera that travels through the pipe, providing detailed internal images. These images help identify the pipe’s condition, material, and any challenges that might affect the bursting process, like severe collapses or nearby utilities. Based on the inspection, a detailed plan is formulated, including the selection of the appropriate bursting head size and the new pipe material.

Step 2: Site Preparation

Once the initial inspection is complete, the next step is to prepare the site for the bursting operation. This involves creating small access pits at strategic locations—typically at the beginning and end of the section to be replaced. These access points allow for the insertion of the bursting equipment and the new pipe. All necessary permissions and safety measures are secured during this phase to ensure a smooth operation.

Step 3: Equipment Setup

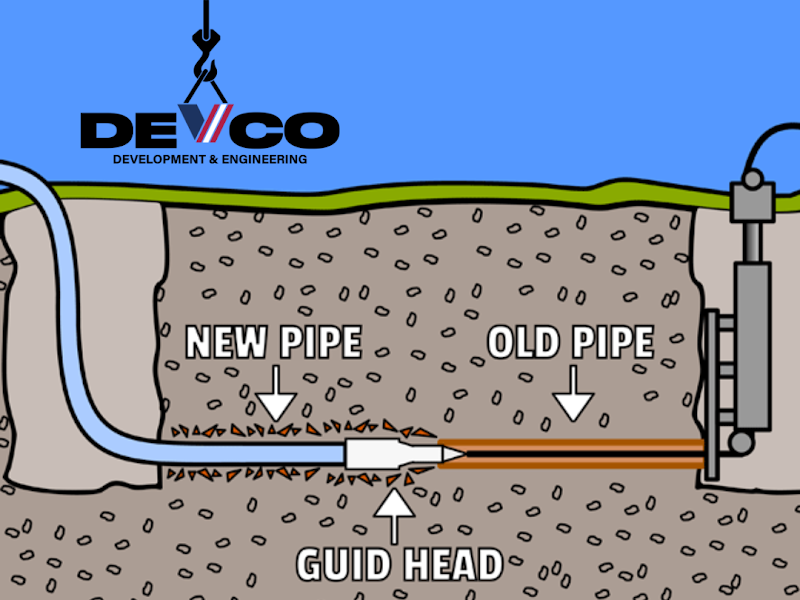

With the site prepared, the equipment needed for the pipe bursting is set up. This includes the bursting head, which is attached to a steel cable or hydraulic rod system, and the new pipe, which is often made of high-density polyethylene (HDPE) for its durability and flexibility. The equipment’s design allows it to navigate bends and obstacles within the existing pipeline, making it versatile for various applications.

Step 4: The Bursting Process

The core of the operation is the bursting process itself. The bursting head is inserted into the existing pipe through the access pit. As it is pulled through the pipeline, it fractures the old pipe outward into the surrounding soil. Simultaneously, the new pipe, attached behind the bursting head, is pulled into place along the same path. This step is carefully monitored to ensure precise alignment and integrity of the new installation.

Step 5: Reconnections and Testing

After the new pipe is in place, the next step involves reestablishing connections to lateral services and conducting rigorous tests to ensure the system is functioning correctly. This might include pressure tests, leak detection, and another CCTV inspection to confirm the new pipeline’s condition and proper installation. Ensuring that all connections are secure and that the system operates as intended is crucial for the longevity of the new pipe.

Step 6: Site Restoration

The final step in the pipe bursting process involves restoring the site to its original condition. This includes filling in the access pits, compacting the soil, and repairing any surface materials disturbed during the operation, such as pavement or landscaping. The goal is to leave the site with minimal signs that a major underground installation or repair was completed.

Advantages of Pipe Bursting

Choosing pipe bursting for underground utility installation or repair offers numerous benefits:

- Minimal Disruption: With only small access pits needed, pipe bursting significantly reduces surface disruption compared to traditional excavation methods.

- Cost-Effectiveness: Less surface restoration and quicker completion times make pipe bursting a cost-effective solution.

- Environmental Conservation: Trenchless methods like pipe bursting have a lower environmental impact, preserving the site’s integrity and reducing the carbon footprint associated with extensive excavations.

Whether dealing with a sewer line, gas line, or other underground utilities, pipe bursting represents a modern, efficient, and effective solution. By understanding the steps involved, you can better appreciate the technology’s value and why it’s increasingly becoming the preferred method for underground utility installations and repairs.

Remember, whether it’s called pipe bursting, pipe splitting, or trenchless pipe repair, this innovative technique stands as a testament to the advancements in underground utility work, offering a less invasive, more environmentally friendly, and efficient alternative to traditional methods.